Grinding, sanding and polishing

Grinding and polishing are techniques used to embellish a product. These techniques are applied when the quality of the material surface needs to improve, or whenever the surface needs to be prepared for a coating.

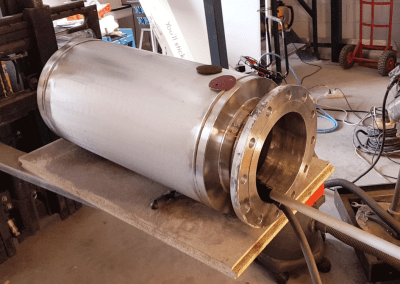

Despite the appearance of similarity of the technique, they differ completely. For example, grinding is used to remove gross damage or uneven metal structures caused by corrosion. The material will be polished after the grinding part is finished. The grinding technique is applied in two states. First a relatively coarse grain will quickly remove all unnecessary materials. When this process is completed, the surface will get another grinding but this time with a finer grain.

When the grinding treatment is finished any remaining imperfections will be brushed away after which the material will be polished.

Grinding and polishing are used as a final treatment for the surface. These finishing touch techniques are done with various methods. Among other things there is; grinding with different grits, brushing, “scotch-briden” and high-gloss polishing. Often are these techniques used to improve the look of the material. However in some sectors there is a different reason to smooth out the steel surfaces. In those cases the smooth surface will help to prevent any attachment.

Professional Grinding, sanding and polishing

By using VERM Services for your grinding, sanding and polishing, you can count on the best of results!

Different materials

Materials such as copper, brass, zamac, steel and aluminum are treated as a preparation for the attachment of a decorative layer, such as chrome or nickel. Irregularities will be removed, after which a gloss layer will be attached. This could be a high gloss, a semi gloss or a matte layer.

A comparison for grinding and polishing:

Both techniques will smooth out the material.

Both techniques are used as a final treatment on aluminum and stainless steel.

The techniques differ from matte to semi gloss to high gloss

Grinding and polishing requires a professional approach

Keeping maintenance in mind during the design face of an item will increase the lifespan of an item. If the grinding and polishing maintenance is kept in mind by design, it will be easier to treat all surfaces, even the closed gaps and small corners. Grinding or polishing is done by hand or machine. Dimensionally stable results will be achieved by lathes or grinding machines.

It could be necessary to remove objects of an item to treat it separately. After the grinding the object will be placed back. The detaching and afterward attaching of objects will consume more time but will be worthwhile. This approach will keep the grinding costs low, improve the cosmetic appearance and will give the item the best possible outcome.