The degreasing of steel surfaces

Degreasing results in better attachment. Degreasing a steel surface is an important preparation for the final surface treatment. There will be consequences for the steel surface treatment when the degrease and disinfection is omitted. To obtain a clean and rough surface, the grease particles must be carefully removed. When done properly, the cleaning process will benefit the attachment of the new to apply layers. For example to degrease steel you can use a blasting method.

The removal of grease and oils is crucial, without you will have a poor attachment to the next layer. This poor attachment will continue to disrupt through all next layers in the process.

Grease and oils can contaminate an abrasive, which will contaminate a steel surface.

How do grease particles attach to a surface?

Grease particles can attach to a steel surface in various ways. The most common causes are:

1. Mineral source

These are mainly hydrocarbons consisting of organic compounds and sulfur-containing compounds.

2.Natural source

For example linseed oil, canola oil or tallow.

Degreasings works with the following chemical methods:

1. By dissolving

2. By saponification

There is a distinction made between chemical degreasing in a non-aqueous and an aqueous environment and electrolytic degreasing.

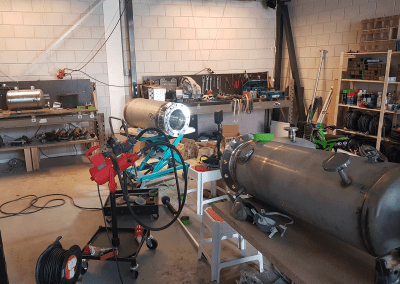

Professional Degreasing of steel surfaces

VERM Services is your partner in advanced surface treatments and metal finishing services.

What degrease method to use?

Existing degrease methods to choose from:

• Electrolytic degreasing

• Emulsion cleaning

• Alkaline cleaning

• Solvent cleaning

• Vapor degreasing

• Acid cleaning

• Ultrasonic cleaning

Degreasing can be done by high pressure spraying, in a dip bath or manually. The end result for degreasing is affected by temperature, bath movement, the duration of the treatment and of course the cleanser type.

The method to choose for degreasing the surface is depending on the below criteria:

1.Technical requirement.

What type of grease must be removed? How high is the required cleanliness? How big is the surface and what are the necessary follow-up treatments? Questions to keep in mind when selecting a specific degrease method.

2.Economical requirement

It is important to keep the economical particularities in mind. For example you have to consider the installation of use and what the cost of this installation could be. Is there any comparison available for the degreasers, treatment and labor costs?

3.Environment requirement

Before starting a new project it is important to be aware of the local legislation, health requirements and storage permit. Next to that you have to be aware of the waste processing regulations.